We all know that plastics have been a part of our daily lives for quite some time. Some might say that plastics are harmful to both living beings and the environment. But why are we still using plastics? I believe many of you have asked the same question. However, blaming plastics solely for these problems isn’t quite fair. In reality, if we use and dispose of plastics correctly, they can provide numerous benefits in various aspects.

As someone who sells packaging, I sometimes feel like a doctor who treats patients in a hospital. While doctors treat and alleviate patients’ illnesses, a packaging seller advises clients on packaging solutions that meet their needs. This helps businesses move forward in the right direction.

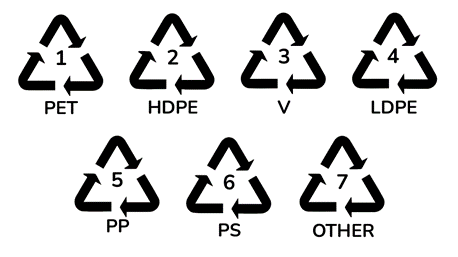

“Wait! Aren’t all plastics the same?” That’s a common question from many customers when they discover that plastics come in different types.

Yes, plastics are not all the same. Depending on their intended use, the materials and production processes differ. I’ve compiled all the information on various types of plastics below, categorized by the recycling symbols you often find on packaging.

Plastic Type 1 (PETE) – Polyethylene Terephthalate:

This type of plastic is strong and has a clear appearance, ideal for water bottles and cups that showcase the beverage inside. PETE can withstand temperatures of up to 70-80°C.

Plastic Type 2 (HDPE) – High-Density Polyethylene:

HDPE is opaque, flexible, and impact-resistant, with heat resistance up to 80-100°C. It’s commonly used for milk jugs, chemical containers, and even toys.

Plastic Type 3 (PVC) – Polyvinyl Chloride:

PVC is durable and withstands pressure and impact well. It’s ideal for flooring, window frames, and plumbing pipes, with heat resistance up to 60-70°C.

Plastic Type 4 (LDPE) – Low-Density Polyethylene:

LDPE is flexible and can resist heat up to 70°C. It’s used for plastic bags, squeeze bottles, and food wraps.

Plastic Type 5 (PP) – Polypropylene:

This plastic can withstand heat up to 120°C and is flexible, making it suitable for microwave-safe containers, plastic bottle caps, and medical supplies.

Plastic Type 6 (PS) – Polystyrene:

PS is the clearest of all plastics, used for disposable cups and packaging, but it’s fragile and can only withstand temperatures up to 70°C.

Plastic Type 7 (Others)

The table below summarizes the properties of each type of plastic, helping you choose the right one for your needs.

Name | Melting Point (°C) | Properties | Common Uses |

Polyethylene Terephthalate (PETE) | 70 – 80 | Durable, semi-flexible, highly transparent | Water bottles, cold drink cups, food containers |

High-density Polyethylene (HDPE) | 80 – 100 | Opaque, flexible, impact-resistant | Milk jugs, chemical containers |

Polyvinyl chloride (PVC) | 60 – 70 | Strong, impact-resistant | Flooring, window frames, plumbing pipes |

Low-density Polyethylene (LDPE) | 70 | Flexible and tough | Plastic bags, squeeze bottles, food wraps |

Polypropylene (PP) | 120 | Heat-resistant, tough, flexible | Microwave containers, plastic bottle caps |

Polystyrene (PS) | 70 | Clear but fragile | Disposable cups, lightweight packaging |

Others | |||

Polymide (PA) | 150-180 | Highly heat-resistant, strong, impact-resistant | · Car parts · Electronic components · Sports equipment |

Acrylonitrile Butadiene Styrene (ABS) | Depends on composition | Strong, tough, impact-resistant, abrasion-resistant, heat-resistant | · Car parts · Children’s toys · Luggage |

Polymethylmethacrylate (PMMA) | 70-80 | More than 90% transparency, tough, impact-resistant, glass substitute | · Fish tanks |

Polycarbonate (PC) | 120-140 | Heat-resistant, acid-resistant, impact-resistant | Baby bottles, Eyeglasses, lenses, Headlights, advertising signs, bulletproof glass, safety glass |

When selecting plastic for use with food, always look for the Food Contact Material Symbol to ensure its safety. However, it’s crucial to follow proper usage instructions, especially when dealing with high temperatures, to ensure consumer safety and sustainable service practices.

Lastly, I sincerely hope this article provides valuable information to all readers. I would like to thank our loyal customers for always trusting Kitchen Class 1993 Co., Ltd. to support and assist your needs.